A plumbing problem in the plumbing of a commercial kitchen can interfere with daily operations, especially if your grease recovery device is overflowing or the whole kitchen drain system is inoperative. As commercial kitchen specialists with decades of industry experience, we have a vast of knowledge when it comes to grease traps, grease interceptors, and plumbing dilemmas.

The role of a grease interceptor or a grease trap (FOGS Device) plays a valuable component in a commercial kitchen’s plumbing. When a drainage dilemma occurs in the kitchen drains or causes the FOGS recovery device to overflow, the problem will likely be due to either a blockage in the plumbing, a grease trap with excessive content, or both.

Knowing How Much Grease & Solids Waste Should Be In A Grease Trap or Grease Interceptor

Have you ever encountered a situation where the kitchen sink is backing up or draining slowly, accompanied by unpleasant odors? This could be indicative of a common yet critical issue in commercial kitchens: grease trap overflow.

The 25% Rule:

According to regulations, grease traps and interceptors should ideally be serviced when the FOGS content reaches 25% of the total wastewater volume. This guideline ensures that the traps are functioning efficiently and preventing excessive grease buildup in the plumbing system.

Overflow Doesn’t Always Mean Full:

Here’s where it gets tricky: an overflowing grease trap doesn’t necessarily mean it’s reached its full capacity. Rather, it indicates that the grease levels have surpassed the recommended threshold. Grease traps can overflow or cause backups even before reaching their maximum capacity if they’re not regularly maintained.

Signs of Excessive Grease:

If you notice backups, slow drainage, or foul odors emanating from drains, it’s likely that the grease trap has exceeded its capacity. This means the FOGS-to-wastewater ratio has gone beyond the allowable 25%. When this happens, it’s crucial to address the issue promptly to prevent further complications.

How to Know When Your Grease Trap Needs Servicing:

- Regular Maintenance: Schedule routine maintenance checks for your grease trap to ensure it’s functioning properly.

- Monitoring FOGS Levels: Keep track of grease levels within the trap and arrange for servicing when it approaches the 25% threshold.

- Visual Inspection: Regularly inspect the grease trap for signs of buildup or overflow, such as grease accumulating near the inlet or outlet pipes.

- Professional Assessment: Consult with plumbing professionals who can assess the condition of your grease trap and recommend appropriate servicing intervals based on usage and FOGS accumulation.

In summary, understanding the dynamics of grease traps and interceptors is crucial for maintaining a hygienic and efficient commercial kitchen. By staying vigilant and adhering to recommended servicing intervals, you can prevent costly backups and ensure compliance with regulations regarding FOGS management.

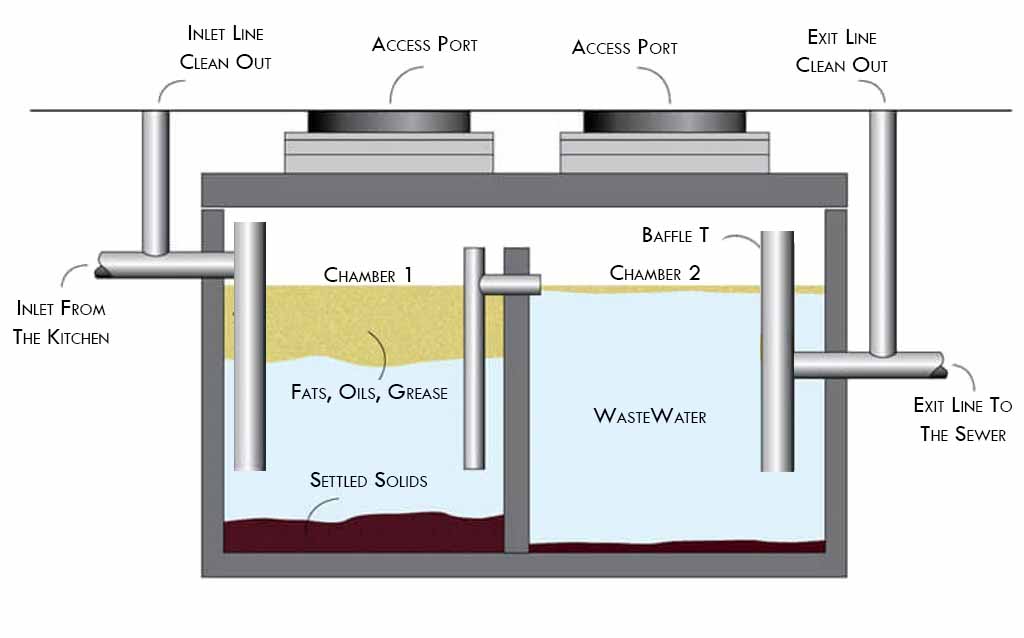

Grease Trap & Grease Interceptor Diagram Basic Functions

A plumbing problem in the plumbing of a commercial kitchen can interfere with daily operations, especially if your grease recovery device is overflowing or the whole kitchen drain system is inoperative. As commercial kitchen specialists with decades of industry experience, we have a vast of knowledge when it comes to grease traps, grease interceptors, and plumbing dilemmas.

The role of a grease interceptor or a grease trap (FOGS Device) plays a valuable component in a commercial kitchen’s plumbing. When a drainage dilemma occurs in the kitchen drains or causes the FOGS recovery device to overflow, the problem will likely be due to either a blockage in the plumbing, a grease trap with excessive content, or both.

Determining If The Grease Trap or Grease Interceptor Is Full

If you are having a drainage issue, the first step is to determine when the FOGS recovery unit was last serviced. A good indicator is, grease traps with less than 100-gallon capacity are serviced monthly, and outdoor grease interceptors above 750 gallons are done quarterly. If you have exceeded the service maintenance increment, this may be the problem that is causing the drains to slow down.

Excessive grease and settled food solid content will prevent the recovery device from performing its job, leading to drain problems. Stagnant or excessive FOGS waste content can prevent liquid waste from entering or exiting the FOGS recovery plumbing fixture. There’s a high probability that when a commercial grease trap or grease interceptor is unmaintained or is not being cleaned on time, the plumbing will start having issues. Be aware that FOGS recovery devices are full when the percentage of fats, oils, grease, and food solids to wastewater ratio top 25%.

Plumbing For Commercial Kitchens

If you have recently had a complete pump out of the FOGS recovery system’s cleaning, it is advisable to have the line hydro jetted to clear out build-up in the plumbing line. Congestion or blockage in the pipes will prevent liquids from passing through. For instance, a jam on the grease trap or grease interceptor’s exit line will obstruct the wastewater from accessing the sewer line overflowing the recovery device. On the other hand, blockage in the inlet into the device will prevent the waste liquid from entering, causing the kitchen’s drains to clog.

Grease & Plumbing Specialists

Suppose you are experiencing a problem with the plumbing in your commercial kitchen. It is advisable to understand better the relationship between the grease recovery device and the plumbing system. Performing simple due diligence can allow you to identify the problem immediately, preventing unnecessary costly service calls. It is crucial to keep up with the suggested scheduled maintenance on both grease trap or grease interceptor cleaning and high-pressure pipe jetting service to stop or prevent plumbing issues. To learn more about restaurant grease recovery devices and commercial kitchen plumbing drains, call us at 888-697-8910.